The assembly of motorcycle engine parts after overhaul is an important work. How to successfully assemble the parts into a complete engine has a high technical standard. Especially the assembly quality can directly affect the service life and maintenance frequency of motorcycle engine in the application process.

When the engine is working, the inner surface of the cylinder liner is in direct contact with high-temperature gas. Its temperature and pressure change frequently, and the instantaneous value is very high, which increases the heat load and mechanical load. The piston makes rapid reciprocating linear motion in the cylinder, and the inner wall of the cylinder plays a guiding function.

The lubrication condition of the inner wall of motorcycle engine parts is poor, and the oil film cannot be produced. In application, it wears rapidly, especially in the area close to the. In addition, the combustion products are corrosive to the cylinder. Under severe working conditions, wear is inevitable. The wear of motorcycle engine parts will affect the performance of the engine.

The assembly points of motorcycle engine accessories are as follows:

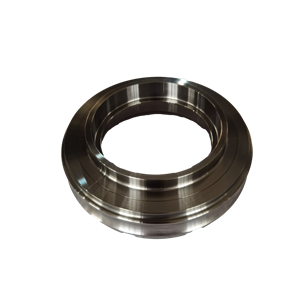

(1) First put the cylinder liner without water stop ring into the cylinder block for a try. It is better to rotate flexibly without obvious shaking. Check whether the step size of the cylinder liner is higher than the plane of the cylinder liner.

(2) Whether the cylinder liner is new or old, a new water stop ring should be applied when assembling motorcycle engine parts. The rubber of the water stop ring shall be soft without cracks, and its specification, model and size shall meet the requirements of the original engine.

(3) When pressing in the cylinder liner, apply some soapy water around the water stop ring to facilitate lubrication. You can also apply an appropriate coating on the motorcycle engine parts, and then gently push the cylinder liner according to the indicated cylinder bore serial number. Slowly press the cylinder liner into the cylinder block with a special assembly tool in the corresponding cylinder hole to make the shoulder closely fit the upper surface of the cylinder stop.

After the motorcycle engine parts are assembled, measure with an inner diameter dial indicator, and the deformation of the water stop ring shall not be greater than 0.02mm. In case of large deformation, pull out the cylinder liner, repair the water shutoff ring and reinstall it. After the cylinder liner is assembled, the upper shoulder of motorcycle engine accessories shall protrude 0.06 ~ 0.12mm from the cylinder plane.

Scan QR code and add Huanye wechat